|

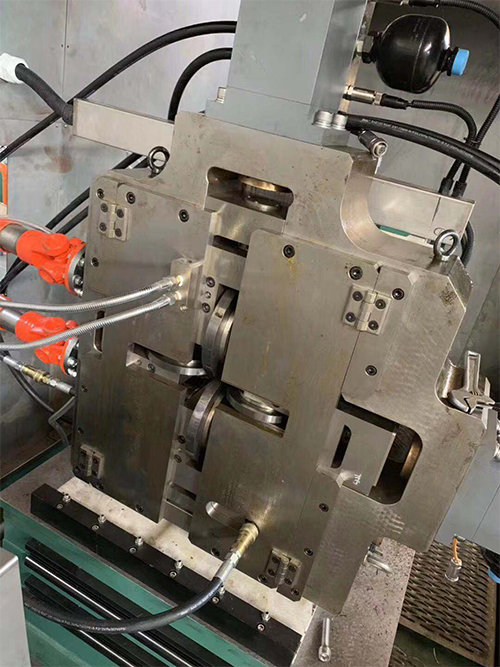

Our main rolling mill machine description

flat wire rolling mill Product Description

High Precision flat wire rolling mill machine line | Rolling Material | high carbon, medium carbon, low carbon steel wire, stainless steel wire, titanium wire, titanium nickel alloy wire and other | | Roller Material | tool steel, sintered metal or carbide steel, alloy steel | | Roller diameter | 150-350m | | Roll accuracy: | Roll accuracy: | | Tolerance | Thickness+/-0.002mmwidth+/-0.005mm | | R-angle type | Nature angle R-angleRoll forming angle special shaped angle | | Take-up method | Spool take-up or automatic cutting machine | | Optional system | guide wire device, rolling force measurement system, central lubrication system, etc. | | Uses | special designed to replace traditional dies used on rectangular, square wires, profile wires |

precision flat and profile wire rolling mill line

Product Description

precision wire rolling mills

It can be used not only in rolling high precision triangular wire from round inlet wires but also used for not rolling triangular wire, square wires, rectangular, Wedge wire, pentagonal wires, hexagonal wires, semicircular wires.

Application industry: oil screen, coal washing screen, environmental protection engineering, engine piston rings, die springs, locks, clutches, medical equipment, pneumatic tools, glasses parts, handlebars, watch bands, electrical parts, clothing mechanical parts, etc...

process: shapes can be cold-rolled if the cross-section is relatively uniform and the transverse dimension is relatively small. Cold rolling shapes requires a series of shaping operations, usually along the lines of sizing, breakdown, roughing, semi-roughing, semi-finishing, and finishing.

Roll diameter: 75-350mm

Main power: servo motor or three-phase asynchronous motor

Press-down mode: electric or manual

Optional devices: guide wire device, roll force measurement system, central lubrication system, etc.

Features:

1.2 type can choose, the one is needed replacing the rolls when forming different wire, the other doesn't need

2. reduces overall separating force required for reductions

3.reduces overall energy needed for reducing material

4.produces more consistent thickness output

5. We can improve the design according to the needs of different customers

Turks Head Mill

Turks Head Rolling Mill It is possible to perform high precision flat& profile rolling experiments from round or profile wires, Generally, the turks head rolling mill is used for research new projects and feasibility studies with different materials, like stainless steel wires, brass wires, and etc. roduct Description DrivenTurks head rolling mill Turks head rolling mill flat and shaped wire rolling machine Model:GZW250 It is possible to perform high precision flat& profile rolling experiments from round wires, Generally, the rolling mill is used for research new projects and feasibility studies with different materials, like stainless steel wires, brass wires, and etc. To achieve a high precision of the process, it is possible to perform thermo-mechanically coupled simulations of the process. Uses: used for rolling shaped wire, one set roll is suitable for one wire. Applying material: suitable for carbon steel wire, stainless steel wire, titanium wire, titanium nickel alloy wire, aluminum wire, brass wire and other non-ferrous and ferrous metals

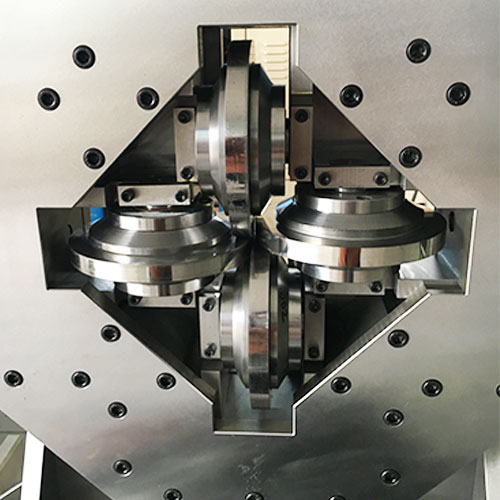

Cassette Roller Dies

Product Description

Universal Rolling Die/ turks head dies/ turkshead/cassette roller die, profile wire drawing die/flat wire rolling die/rolling mill die

Model: GLWC-170

Uses: GLWC series rolling cassettes can be used to roll small or medium cross-section to flat and profiled wire directly. they are specially designed to replace traditional dies used on profile wire drawing lines.

Applying material: high-carbon, medium-carbon, low-carbon steel wire, stainless steel wire, titanium wire, titanium nickel alloy wire, copper wire, aluminum wire, brass wire and other non-ferrous and ferrous metals.

Attributes: No drive.

Advantages: Its working life is productive than the profiled dies so that improving efficiency, saving cost and could change the polishing technology for user.

It can be operated without lubricating oil (dry operation) in a special case.

Different from the drawing die with " one model one die ", possibilty of roller non-replacing when forming profiled wires.

Features: high precision, long service life, high cost.

Roll material: tool steel, sintered metal or carbide steel.

Roller diameter: 170mm

Uses method: usually equipped with tractor or wire drawing machine

Optional devices: guide wire device, rolling force measurement system, central lubrication system, etc.

The outlet wire&strips from our rolling mills

Application Field Our Precision cold rolling mills are mainly used in triangle wire, square wire, flat wire, oval wire, drop wire, Z-shaped wire, wedge wire, polygonal wire, etc.; Application industry: oil screen, coal washing screen, environmental protection engineering, engine piston rings, die springs, locks, clutches, medical equipment, pneumatic tools, glasses parts, handlebars, watch bands, electrical parts, clothing mechanical parts, etc... |

|