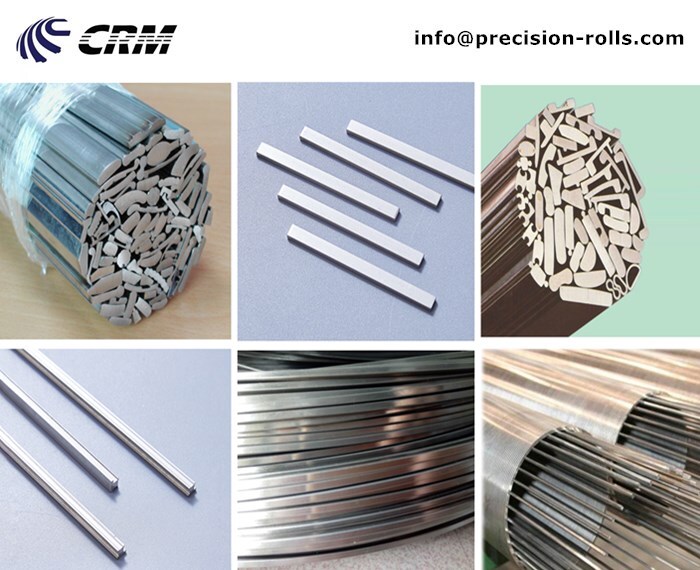

Square wire

Product Details:

- Type Cold Rolling Mill

- Material copper wires

- Capacity 110 m/min Ton/day

- Computerized Yes

- Automatic Grade Automatic

- Control System PLC Control

- Voltage 140 Volt (v)

- Click to View more

Square wire Price And Quantity

- 1.00 - 2.00 USD ($)/Meter

- 1.0 USD ($)/Meter

- 1 Meter

Square wire Product Specifications

- 1 year

- Automatic

- Yes

- Cold Rolling Mill

- 110 m/min Ton/day

- copper wires

- 140 Volt (v)

- PLC Control

Square wire Trade Information

- Shanghai,China

- 12 Meter Per Year

- 20 Days

- Contact us for information regarding our sample policy

Product Description

Profiled copper wire/wire rolling machine manufacturers,factory,China,supplier

Stainless steel 304, 304L, 316, 316L, or as your need

Made by CRM Rolling Mills

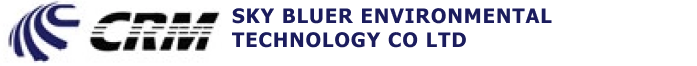

The bare flat copper wire produced by our company is widely used in the manufacture of electrical machines, transformers, welding machine winding wires and other electrical general flat wires for the installation of power distribution equipment.

CRM Product introduction

The bare flat copper wire produced by our CRM Precision rolling mill machine is widely used in the manufacture of electrical machines, transformers, welding machine winding wires and other electrical general flat wires for the installation of power distribution equipment.

As an important basis for enterprises to make plans for purchasing, production and sales of raw materials, flat copper wire products are of great importance to the production, operation and development planning of enterprises. In terms of physical properties, the bare flat copper wire is soft and has excellent conductivity. It is also widely used in electric tools, ballasts, automotive electronics, refrigerator and air conditioning compressor motors, TV sets, electric furnaces, microwave ovens, various transformers and other electronic coil motors and appliances.

About our company

CRM rolling mills develops and produces rolling mills for cold forming applications and cold rolled wire products. Our wire rolling machines are being used worldwide in the automotive, electrical, food, textile and building industry.

Our scope of delivery encompasses the entire range from stand-alone units to turn key solutions for shaped, flat and round profiles made of ferrous and nonferrous wires, as well as stainless steels.

Our consulting services cover the design of all necessary processing steps, the layout of the roll geometry and eventually, also rolling trials.

CRM rolling mills combine latest technologies with state-of-the-art CNC controls, recipes and process visualisation und thus, minimise set-up times so that both small and large batches can be produced very efficiently. Integrated measurement systems ensure consistent product qualities and high-precision rolling processes.

Precision rolling mills/Profile rolling mills

shapes:flat.rectangle,square

Material: Stainless steel 304, 304L, 316, 316L, or as your need

shapes:round,rectangle,rectangular,flat,square,wedge,oval,special-shaped

Length/Width: Customized on demand

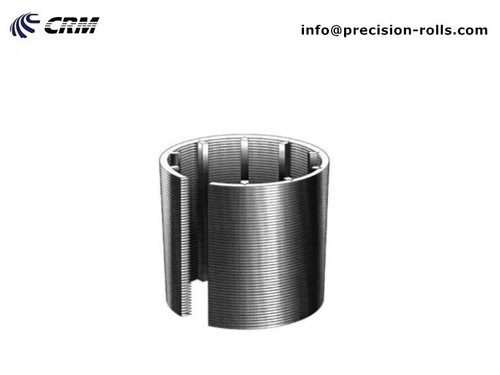

Minimum slot size: 20

Thickness: Customized on demand

Filter form: Surface filtration

The wedge wire screen panel is an important working part of the screening machine to complete the screening process. Each screening machine must select a sieve plate that meets its working requirements. The various characteristics of the material, the different structures of the sieve plate, the material, and the various parameters of the sieve machine have a certain influence on the screening ability, efficiency, running rate, and life of the vibrating screen.

Different materials and different places should use different sieve plates to achieve the best effect of screening. The sieve plate should have sufficient strength, a high opening ratio, and difficulty in plugging holes. When the vibrating screen vibrates, the wedge wire sieve plate passes through materials of different shapes and sizes, material size, and under the action of vibration force, the materials of different particle sizes are separated to achieve the purpose of classification.

The precision rolling process includes mold making, bar heating, finishing rolling forming, finishing straightening and other processes. Compared with the existing cross wedge rolling rough rolling technology, the material saving rate is increased by more than 10%, and the comprehensive mechanical properties of parts are increased by more than 5%. The tolerance zone of the finished product rolled out by precision rolling is about 1/2 smaller than the high-precision tolerance of the international standard. The rolled bar and wire can be directly ground without drawing or cutting. Therefore, the demand for precision rolled steel is increasing year by year, especially for some high-grade alloy steels, the cost of raw materials is high, and precision rolling has its special significance

Welcome contact us

whatsapp 0086 13861313954

info@precision-rolls.com

www.precision-rolls.com

Get a Quote

Get a Quote

Contact Us

Contact Us Send Inquiry

Send Inquiry Send SMS

Send SMS